Floor Polishing

Floor Polishing

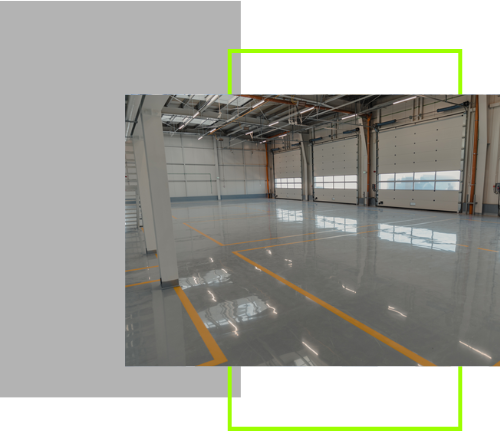

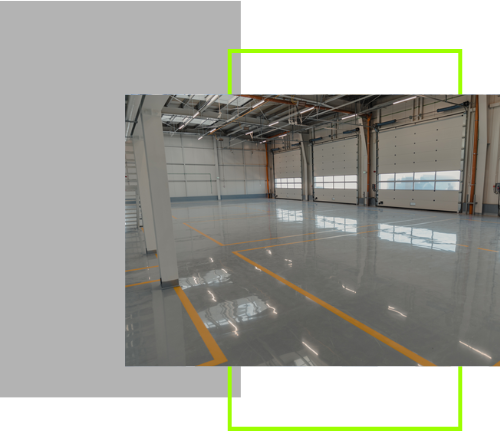

Concrete floor polishing is a specialized service that enhances the beauty and longevity of concrete floors. This process transforms a conventional floor into a brilliant, durable, and aesthetically appealing surface. The technique involves grinding, honing, and polishing floors using high-grade equipment and diamond-infused discs. The outcome is a glossy, reflective finish that not only elevates the look of the space but also offers a variety of practical benefits.

Process Of Floor Polishing

The process begins with the evaluation of the concrete surface. This initial step is crucial as it determines the level of grinding required. Typically, the process starts with a coarse grinding phase where diamond-embedded segments are used to smoothen the surface. This phase helps in removing any existing coatings, minor pits, blemishes, or stains. The coarse grinding also levels the floor, preparing it for further refinement.

Once the initial grinding is complete, the process moves to finer grits of diamond abrasives. These progressively finer grinding stages refine the concrete surface, removing scratches and imperfections. The floor becomes smoother and more refined with each pass. During these stages, the concrete starts to develop a sheen as the process moves through the stages

In the honing phase, the objective is to enhance the smoothness and gloss of the floor. This stage often involves the use of diamond abrasives with finer grits, which buff the concrete to a high shine. The honing process not only improves the aesthetic appeal of the floor but also strengthens it by increasing its density. This enhanced density makes the floor more resistant to wear and tear, extending its lifespan.

The final phase is the polishing stage, where the highest level of shine is achieved. In this phase, even finer diamond abrasives are used, often in combination with a chemical hardener. The hardener penetrates the concrete, reacting chemically to create a tough, crystalline structure. This process not only increases the durability of the floor but also makes it resistant to water, oil, and other contaminants.

The result is a sleek, mirror-like finish that transforms the appearance of any space. The polished concrete floor is not only visually appealing but also highly functional. It is easy to clean and maintain, requiring minimal upkeep compared to other flooring options. Its reflective surface can also enhance the brightness of an area, reducing the need for additional lighting.

Benefits Of Floor Polishing

One of the most significant advantages is the durability. These floors are resistant to heavy foot traffic, making them ideal for commercial and industrial settings. They are also less susceptible to damage from heavy objects, spills, and stains.

Another key benefit is their eco-friendliness. Concrete polishing does not require the use of additional materials like adhesives, coatings, or coverings. This aspect makes it a sustainable flooring option with a minimal environmental footprint. The longevity further contributes to their environmental sustainability, as they rarely need to be replaced.

They also contribute to improved indoor air quality. Unlike some flooring materials, they do not harbor dust, allergens, or mold. This characteristic makes them an excellent choice for individuals with allergies or respiratory issues. Additionally, the ease of cleaning reduces the need for harsh chemical cleaners, further contributing to a healthier indoor environment.

The versatility is another aspect that makes it a popular choice. It can be customized in various ways, including the addition of dyes or stains to create unique color effects. The level of sheen can also be tailored, from a satin finish to a high gloss, depending on the desired aesthetic. This flexibility allows polished concrete floors to complement a wide range of design styles, from industrial to modern.

Make Spartan Coatings Your Choice

Transform your floors with Spartan Coating's concrete floor polishing service and experience a world of benefits. Say goodbye to ordinary floors and welcome durable, attractive, and low-maintenance surfaces into your life. Not only does this service enhance the aesthetics of your space, but it also comes with ecological advantages, making it an environmentally responsible choice. Whether you have a commercial, industrial, or residential space, Spartan Coating's concrete floor polishing shines with its beauty, resilience, and sustainability. Our expertise in delivering this service is a testament to our commitment to quality and customer satisfaction. Contact us today and begin the journey to transform your floors into a masterpiece of craftsmanship and sustainability.

Frequently Asked Questions

Q1. Can These Floors Enhance Acoustics for Home Musicians?

A1.Interestingly, polished concrete floors can indeed influence the acoustics of a room, making them a unique choice for home musicians and audiophiles. The hard, smooth surface reflects sound waves differently than carpeted or wooden floors. This can result in clearer and more pronounced sound quality, especially for certain types of music or instruments. However, it's important to note that this can also lead to increased reverberation, so some additional acoustic treatment may be required to achieve the desired sound quality.

Q2. Is It Possible to Integrate a Heating System Underneath Polished Concrete Floors for Cooler Climates?

A2: Yes, integrating a heating system is not only possible but also increasingly popular, especially in cooler climates. This method, known as radiant floor heating, involves installing heating cables or tubes under the concrete before it is poured. Once the system is activated, it heats evenly, turning the floor into a large, efficient radiator. This not only provides a comfortable, even heat throughout the room but also is energy-efficient and can reduce overall heating costs. ht

Q3. Can Polished Concrete Be Used to Create a 'Glow-in-the-Dark' Effect for Nighttime Ambiance?

A3: Creating a 'glow-in-the-dark' effect is a unique and innovative idea. This can be achieved by incorporating phosphorescent aggregates or coatings into the concrete mix or applying them during the polishing process. These materials absorb light during the day and emit it slowly, creating a subtle, glowing effect at night. This feature can add an enchanting ambiance to outdoor areas, pathways, or even indoor spaces, providing both aesthetic appeal and functional low-level lighting.

All Rights Reserved | Spartan Coatings